The first is the installation environment of the stainless steel gear pump:

1. Ensure ventilation

Pump experts know that the pump needs ventilation to prevent the body from overheating. Therefore, the pump installation location must ensure adequate ventilation and prevent the risk of fire. This means that all pumps installed on the ground must be installed at least three feet away from walls and other equipment.

2. Prevent overheating

Blockage of the suction port or the discharge port is one of the most important causes of stainless steel gear pumps. Therefore, it is necessary to check the filter screen of the suction port from time to time to ensure that it is not blocked to eliminate the safety hazard of the pump and prolong its service life. Make sure that the pump has sufficient air circulation to cool the engine. However, some pumps tend to overheat from time to time without any direct cause. In this case, the first thing the pump operator must do is to shut down immediately and let the pump cool down. Direct contact with the overheated pump may cause severe burns or scalds, so you must stay away from the overheated pump until it cools to room temperature.

3. Install the motor correctly

The motor-driven pump must be properly grounded to reduce the risk of electric shock for employees. If the installation method is not correct, the pump may short circuit. It is the responsibility of pump station workers to ensure that all electrical installations comply with national and local electrical codes and regulations. Different regions have different requirements for line grounding. Before servicing the motor-driven pump, be sure to cut off all related circuits.

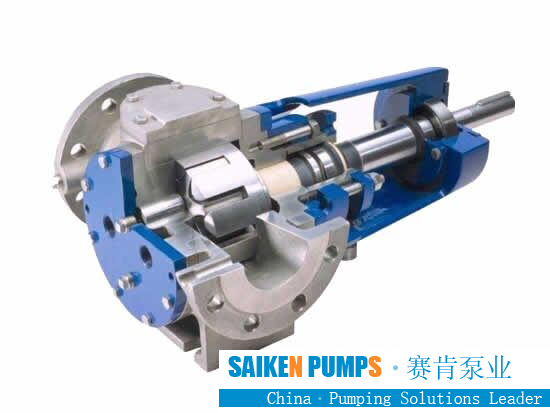

Regarding the maintenance of the pump, the stainless steel gear pump can be repaired online, and the pump cover can be directly removed for maintenance and spare parts replacement.

4. Personal safety

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501