• 3-Phase 220v/380 AC, 33.3 L/m or 9 gpm, 1.45 Mpa or 210 psi, Max 3 HP, 1 Year Warranty

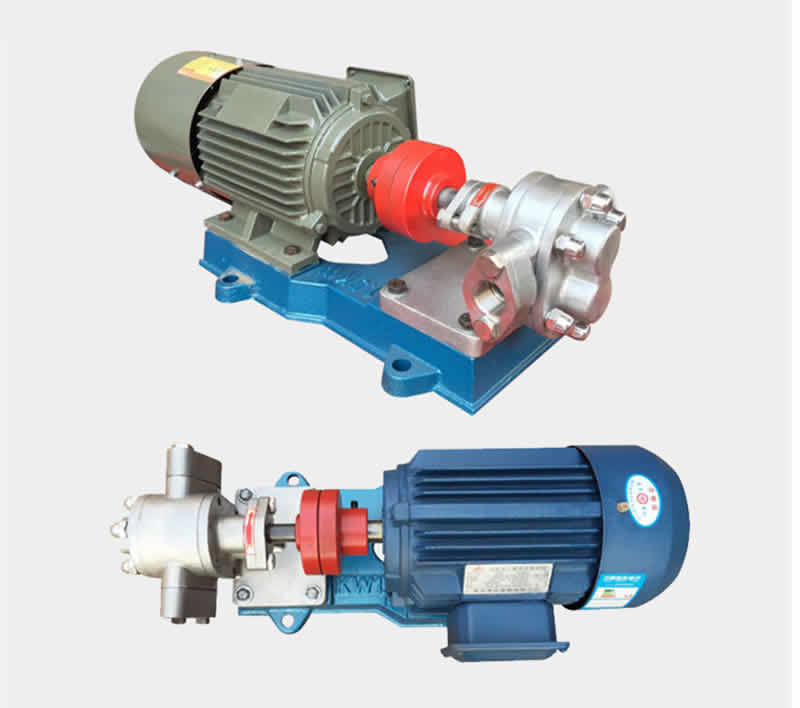

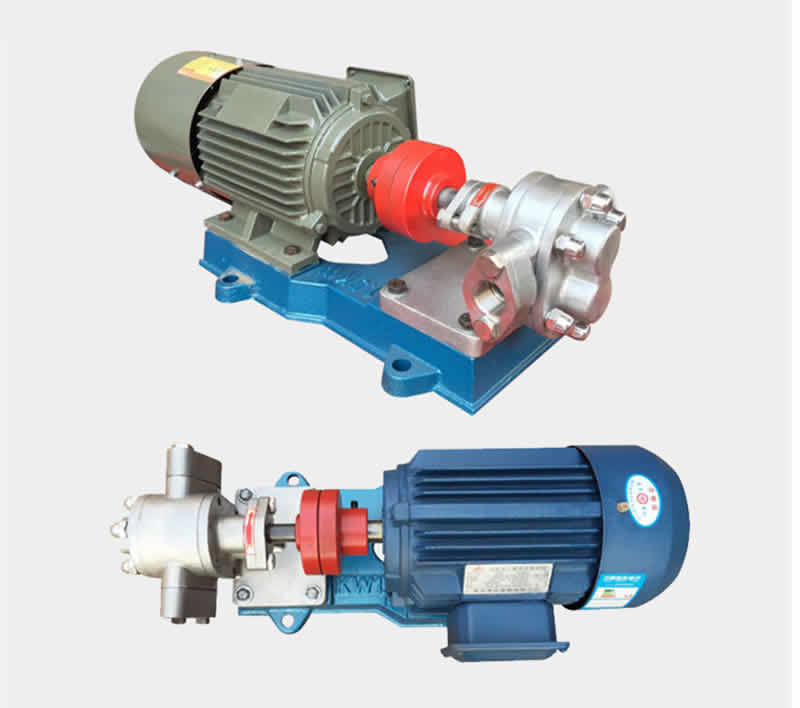

• Gear Oil Pump

• 3/4" inch

KCB 33.3 gear oil pump may be used for pumping oils and fuel oils such as diesel, vegetable oil, Palm Oil, kerosene, biodiesel, motor oil, and even glycerol (waste product in biodiesel process).

KCB 33.3 gear oil pump may be used for pumping oils and fuel oils such as diesel, vegetable oil, Palm Oil, kerosene, biodiesel, motor oil, and even glycerol (waste product in biodiesel process).

This pump can handle viscous fluids such as vegetable oil, motor oil and glycerol if used properyl. When the oil is hot and of low viscosity, the pump should be able to pump it without any problems. If the oil is cold and viscous, the pump may need a small jump start to get it running up to full speed. In order to do this, install a ball valve somewhere on the suction side of the pump. Close the ball valve and turn on the pump. Once the pump is up to full rotation (1 second or less) the ball valve can be opened and it should pump the oil with no problem. This may also be done by removing the suction line from a tank of oil. Allow the pump to suck air first to get up to speed, then dump the suction hose into the tank and it will suck the oil through easily. The pump has a high rotation rate, so if the pump starts with viscous fluid already in the lines, the pump will struggle to get up to speed and will use too many amps and overheat. Allowing the pump to get up to full speed prior to introducing thick fluids is recommended. Typically, this pump does not need any sort of assistance for fuel oils such as diesel fuel. Vegetable oil is typically easy for this pump to handle. When you get into really viscous oils such as motor oil and glycerol, the pump does have limitations. If it is too viscous, the pump will have a reduced duty cycle. We have pumps designed for motor oil which will do a better job but typically with lower flow rates, in this case you may select NYP Internal Gear Pump or NYP Rotary Gear Pump.

The gear pump is a pump attached to the motor by a shaft. The pump itself is all metal (metal gears) and can pump hot fluids without overheating the seperated motor. The motor is high power and has thermal protection, which will automatically shut off the pump in case of the risk of overheating.

These pumps create powerful suction and are self-priming. They can run dry for intermediate amounts of time, allowing for the use of a suction hose for collecting fluids from a tank. They should not be run dry for an extended period of time as oil is required to lubricate the pump head. The metal gears which drive the pumping action can handle a lot of fluids, even if partially dirty. In the case of vegetable oil, any soft particles will pass right through the pump wilth no problems, and are often pulverised by the gears themselves. Hard materials, such as metals, should not be allowed to pass through the pump to prevent damage.

Waste Vegetable Oil Collection:

These pumps have high suction power and are great for collecting vegetable oil from tanks. Whether simply transferring oil or collecting oil, these pumps deliver fast pumping with no need for priming the suction hose.

Biodiesel:

These pumps are considered to be much safer for biodiesel production than the harbor freight clear water pumps since the pump is seperate from the motor. The advantages of the continuous functionaily and high flow rates make this an excellent pump for a biodiesel processor. It will pump the waste vegetable oil, biodiesel and even glycerin without any trouble.

Viscous & Cold Oils:

This pump can handle viscous fluids such as vegetable oil, motor oil and glycerol if used properyl. When the oil is hot and of low viscosity, the pump should be able to pump it without any problems. If the oil is cold and viscous, the pump may need a small jump start to get it running up to full speed. In order to do this, install a ball valve somewhere on the suction side of the pump. Close the ball valve and turn on the pump. Once the pump is up to full rotation (1 second or less) the ball valve can be opened and it should pump the oil with no problem. This may also be done by removing the suction line from a tank of oil. Allow the pump to suck air first to get up to speed, then dump the suction hose into the tank and it will suck the oil through easily. The pump has a high rotation rate, so if the pump starts with viscous fluid already in the lines, the pump will struggle to get up to speed and will use too many amps and overheat. Allowing the pump to get up to full speed prior to introducing thick fluids is recommended. Typically, this pump does not need any sort of assistance for fuel oils such as diesel fuel. Vegetable oil is typically easy for this pump to handle. When you get into really viscous oils such as motor oil and glycerol, the pump does have limitations. If it is too viscous, the pump will have a reduced duty cycle. We have pumps designed for motor oil which will do a better job but typically with lower flow rates.

If used in a hazardous environment, can be use KCB Magnetic Drive Gear Oil Pump,No coupling is safe.

If used in a hazardous environment, can be use KCB Magnetic Drive Gear Oil Pump,No coupling is safe.

System Piping:

A solid pipe or rigid hose is required for these pumps on the suction side. If a flexible hose is required, we recommend using the trash suction hoses which can easily retain shape with high suction power applied through them.

Notice:The gaskets for the flanges do not have holes cut out to protect the pump from collecting debris in the gear during storage and transit.

KCB Gear Pump Technical Parameters:

KCB Gear Pump Technical Parameters:

|

KCB Gear Pump Technical Parameters

|

||||||

|

Model

|

KCB33.3

|

KCB55

|

KCB83.3

|

KCB200

|

KCB300

|

|

|

Flowrate

|

18.3 L/m (5 gpm)

|

33.3 L/m (9 gpm)

|

55 L/m (14.5 gpm)

|

83.3 L/m (22 gpm)

|

200 L/m (53 gpm)

|

300 L/m (80 gpm)

|

|

Pressure

|

1.45 Mpa (210 psi)

|

1.45Mpa(210psi) 0.33 Mpa (45 psi)

|

0.36 Mpa (52 psi) (Adjustable)

|

|||

|

Max Suction Height

|

5 meters (16 feet)

|

|||||

|

Max Head

|

30 Meters

|

|||||

|

Pump Housing

|

Cast Iron

|

|||||

|

Dimensions (LxWxH)

|

22"x9"x10"

|

22"x9"x10"

|

22"x9"x10"

|

27"x10"x11"

|

30"x11.5"x15"

|

31"x14"x15"

|

|

Input Voltage

|

110v AC / 60 Hz

|

220v AC / 60 Hz

|

||||

|

Rotation Speed

|

1750 rpm

|

|||||

|

Max Power

|

1.5 KW (2 HP)

|

2.2 KW (3 HP)

|

1.5 KW (2 HP)

|

2.2 KW (3 HP)

|

5.5 KW (7.3 HP)

|

|

|

Inlet/Outlet Threads

|

3/4" NPT

|

3/4" NPT

|

1" NPT

|

1.5" NPT

|

2" NPT

|

3" NPT

|

|

Weight

|

75 lb

|

78 lb

|

78 lb

|

95 lb

|

248

|

281

|

|

Warranty

|

1 Year against manufacturer's Defects

|

|||||

+8617731766260/18233754501

+8617731766260/18233754501  fan@saikenpumps.com

fan@saikenpumps.com

+8617731766260/18233754501

+8617731766260/18233754501 +86-317-8227664

+86-317-8227664

+8618233754501

+8618233754501